Tom Gardner - tgardner@ecn.purdue.edu

The following tools and materials will be needed (not including all the necessary wrenches and sockets):

- Cardboard, any box will do.

- Pencil and scissors, to mark and cut cardboard.

- Sheet of 1/8" plate steel, approx. 30" X 10", thickness may vary with your needs.

- Reciprocating Saw or Cut-Off saw, anything to cut the steel plate.

- Grinder, small handheld works best.

- Welder, MIG, TIG, stick, or... whatever you are familiar with.

Procedure

- Now you can start on the disassembly of the rear suspension.

- Block the front tires, jack up the car, support the rear axle with a shop jack, and support the car with jack stands under under the frame.

- Remove the wheels and loosen all the bolts for the control arms (CAs). (all the nuts are deformed nuts, so they are tight)

- Remove the rear sway bar.

- Remove the upper and lower CAs, making sure the rear axle stays on the jack. (if you are going to replace the bushings. WAIT. leave the old ones in until the boxing is complete, to prevent any warping)

- Cut templates out of the cardboard for each CA . (on the open side of the upper CA make sure you allow room for the bushing and the proper swing of the arm.)

- Transfer the dimensions on to the steel plate and cut out each piece.

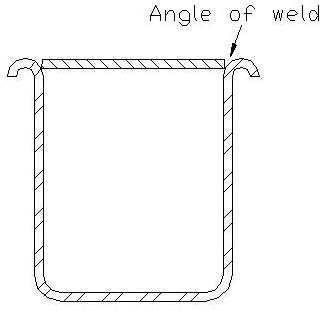

- Take the grinder and custom fit each piece into a CA. Make the piece fit into the contour of the CA, (see diagram below), and make a slight bevel to allow for better weld penetration

Cross section of control arm and steel plate. - Take the grinder and custom fit each piece into a CA. Make the piece fit into the contour of the CA, (see diagram below), and make a slight bevel to allow for better weld penetration

- Now weld in each piece. I angled the gun into the gap, and slightly moved left to right to fill the gap, this is with a MIG. Do it whatever way you are comfortable with, and can get the best penetration of both the CA and the plate.

- Weld in short burst, maybe 2-3 seconds long, then move to a new spot or even a different piece. This will prevent any warping of the plate or the CA.

- After you have a good continuos weld, let them cool, clean and paint them so they do not rust.

- Now is the time to replace those bushings.

- Bolt the CAs back up, reconnect the sway bar, and put the wheels back on.

Now you can feel free to light up the tires on those raining days, without looking like a fool with your tires bouncing up and down.