Jerry Turner - jfturner@cswnet.com

For those of you who like to do things yourself or can't afford one of the "custom" built downpipes, can possibly do what I've done-I made my own version....I call it a JTDP :->)

For those of you who like to do things yourself or can't afford one of the "custom" built downpipes, can possibly do what I've done-I made my own version....I call it a JTDP :->)

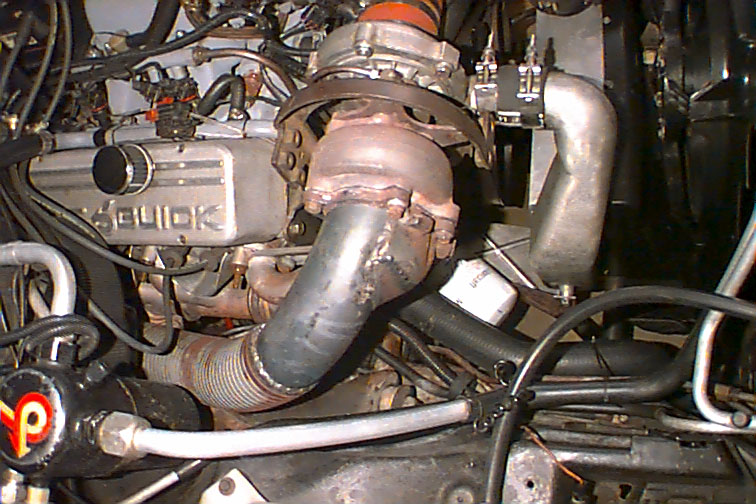

Folks, I sure by now that you know I don't have the gift of gab (can't explain myself to well) so I've attached a picture of the final product in hopes that the adage "a picture is worth a thousand words" will apply in helping those that wants to try this "at home" modification.

The final results is a much quicker turbo spool up and the exhaust noise is considerably quiter, and above all the satisfaction that it works well and you did it yourself saving a BUNCH of money.

One note-I had a 3" mandrel bent downpipe that I've had on the car for sometime BUT it had the same hookup to the turbo elbow as the stock unit does.

- Jack up the car and remove the right tire/wheel so access to the downpipe can be gained in order to cut if off.

- I cut the downpipe off as far back as I could reach with my reciprocating saw at back of the inner fenderwell opening.

- Make cuts to the turbo elbow that leaves only the bolt flange portion of the elbow AND the "bulge" that covers the wastegate flap/puck.

- Grind out the flange and the "bluge" (do this a little at a time, checking for fit) until the end of the 3" 90 degree pipe fits (tight) inside the stock elbow flange.

- Bolt the modified turbo elbow back onto the turbine housing and start making cuts to the 90 degree pipe (do this a little at a time) until the other end of the 90 degree elbow pipe comes into line with the cut off end of the downpipe.

- Mark both the modified elbow and the 90 degree pipe elbow, remove and take to the weldor for welding.

- To simplify the final hookup to the remaining downpipe (where cut was made) and the end of the new downpipe from the turbo, I use a short piece of 3" flex pipe welding it on to the end of the opposite end 90 degree elbow that attaches to the turbo, then use a band clamp to hook the two pipes together where the downpipe cut was made