|

|

|

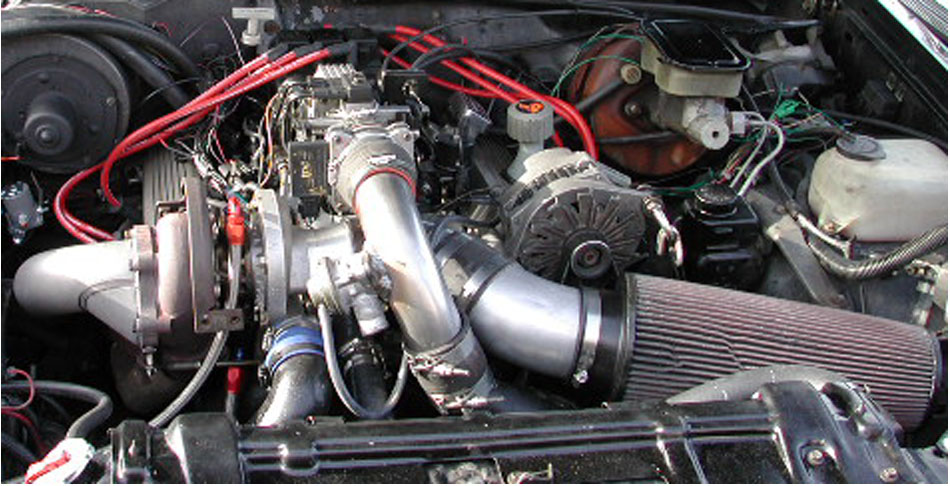

Phase 2 involved shortening the old MAF tubing as much as possible.

Phase 3 incorporatates a 4" Air Filter to Turbo Piping (modified Eastern), and the installation of a 1st Generation Eclipse Blow Off Valve (BOV).

The Eastern Piping originally had three bends in it, but to fit the 14" K+N meant cutting it up and refashioning things.

The BOV in OEM form started to open at 10 PSI. To make it operate at a more respectable boost level, Bruce blocked the reference signal port to the bottom of the diaphragm (along side of the piston). Then he drilled a hole from the side to reference the diaphragm to atmosphere instead. At 22 psi, the valve is still closed that way.

If you look at #5 plug wire, you can see how much more room there is without the HVAC box. In 2D it's hard to see how much more room there really is!

While not fully sorted yet, you can see that Bruce has rewired the loom so it runs down the passenger side of the engine, right by the fuel rail. This makes access a lot easier. As part of the project, Bruce changed the 3" ATR single shot exhaust (too loud) to a Walker Ultraflow 17220 in place of the Pit Bull muffler and then installd the Pit Bull where the catalytic converter was. Now it's much quieter with no noticable loss in performance.